- 共1页 7条

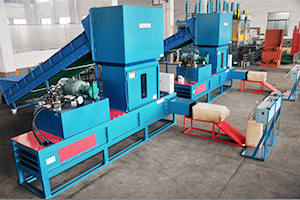

Plastic recycling industry works on recycling cleaning packaging granulating and drawing of plastic bottle in PET or other material. Plastic bottles have a high recycling value. Bottle cap is made of PE label is made of PVC and bottle body is made of PET. All have a certain recycling value. After separating labels and bottles need to be compressed and packed by a baler machine to reduce storage and transportation costs.

Plastic bottle recycling can be divided into recycling center recycle and factory centralized recycle. Usually recycling center will choose vertical or horizontal semi-automatic baling machine according to the recycling amount while factory centralized recycle will adopt horizontal semi-automatic or full automatic baling machine due to the large output. In order to reduce labor cost and improve process capacity usually factory will use conveyor for material feeding.

Solid waste recycling industry has a wide range it including enterprises & institutions waste recycling shipping industry waste recycling car dismantling recycling car interior waste recycling etc. ba

Waste materials in agriculture forestry and farming industries are generally wood chips shavings rice husk cottonseed husk pasture etc. These materials are all finely materials and cannot be bundled into bales. Usually will be bagged or pressed into blocks directly. According to material features and production Jewel ordinary bagging machine high-speed bagging machine square briquetting machine cylindrical briquetting machine can be used. Material can be loaded with belt conveyor or screw conveyor. It can save labor cost and also greatly reduce storage and transportation costs.

Automatic bale compression & wrapping production line is suitable for industries require preventing debris falling or odor emission after the bale be pressed. For example in household garbage recycling industry after crushing and sorting the household garbage and pressing into bales there will be debris falling and have peculiar smell during transportation. It will seriously pollute the environment. In this case clients can choose automatic bale compression and wrapping production line.

Automatic bale compression & wrapping production lines has two types: one is the binding before wrapping the other is non-binding before wrapping suitable for different industries and needs.

Textile packaging is usually for compress and package of finished goods like carpet quilt etc. Four pillars baler vertical baler machine is recommended. After compression and packaging it can greatly save space and transportation cost.

Second-hand clothes recycling including recycling and packaging of wool and other fibers generally requires outer package and cross bundling after compression to effectively prevent material from being contaminated. Lifting chamber model and four sides door open model are recommended. Both can have outer packaging and cross shape bundling.

me

Application: steel mill recycling company lathe chips & scrap waste recycling non-ferrous and ferrous me

Usually the recyclable waste in logistics and supermarket industry are carton and plastic which are generally outer plastic package film and cartons of the product. These waste are featured in large volume.

In logistics industry carton recycling generally has large process capacity requirement clients can choose online conveyor or chain conveyor to transport the cartonswhen equipped with horizontal full automatic baler machine it can realize unmanned operation. If the output is quite large a carton crushing machine can be added to shredder the cartons and then pack the cartons to bales.

In supermarket industry owing to space limit and large number of stores clients generally choose vertical balers to recycle and package waste. As the package cartons normally in big size large feed opening model balers are used in each branch stores to recycle and package waste separately.

02

Advantage

Strict quality control: build quality cornerstone

With strict implementation of ISO quality management system, standardized technical process, operation and maintenance standards, precautions, all staff follow responsibility management, and need to carry out on-job training and assessment, continuous optimizing production safety, quality and efficiency.

01

Advantage

Customized products: help customers multiply their benefits

According to different customers needs, personalized services can be carried out to optimize machine shape, structure,performance, technology, etc., helping customers to further save production cost, and win greater premium space and competitiveness.

04

Advantage

In-sale: engineers with rich project experience gate the process

Whether it is the installation of a single equipment or the commissioning of a complete set of waste discharge system, we will arrange professional technical engineer and construction worker to ensure the normal and efficient operation of the equipment.

03

Advantage

Pre-sale: with professional sales team

We have cultivated a mature sales team which is young, high-quality and professional. Our sales team membershave been on the major industry exhibitions all year round and communicate with customers on sitearound the world. Every employee is expert and talent on the position.

05

Advantage

After-sale:24 hours response to customer demand

7 days ×24 hours rapid response after-sales team, with many years of work experience and emergency handling ability, can timely deal with abnormal problems of equipment during usage, to ensure normal operation of the equipment and smooth production of customer’s manufacturing line.

06

Advantage

25 years of experience:has been the environmental protection packaging equipment industry benchmark

With 25 years experience in research and development of baler machine and waste dispose system, we have a group of professional talents with strong design &development ability, excellent technology, and pursuing innovation. We also work closely with universities and research institutes to always master cutting-edge technologies.

07

Advantage

Customer service: has long-term cooperation with represent customers in all fields

Thanks tothe industry status and brand advantages, Jiabao has been attracting a large number of customers from different countries and regions in the world, and also has a stable partnership with a number of enterprises and institutions in domestic, winning a good reputation in the industry at home and abroad.

Contact US

0086-21-68564313

M essage